Belgian Dark Strong Ale

BJCP 2008 – 18E

Statistics

62.5% Real

Fermentables

| Amount | Fermentable | % |

|---|---|---|

| 22.00 pounds | German Pilsen Malt (2-Row) | 65.4% |

| 6.00 pounds | German Light Munich Malt | 17.8% |

| 2.00 pounds | German Wheat Malt Light | 5.9% |

| 0.50 pounds | Belgian Special B Malt | 1.5% |

| 0.50 pounds | German CaraMunich Malt I | 1.5% |

| 0.50 pounds | Belgian Caravienne Malt | 1.5% |

| 0.13 pounds | British Pale Chocolate Thomas Fawcett and Sons | 0.4% |

| 1.00 pounds | Candi Sugar, Dark | 3% |

| 1.00 pounds | Candi Sugar, Amber | 3% |

| 33.63 pounds | Total Fermentable Weight | 100% |

Hops

| Amount | Hop | Time | Use | Form | AA | |

|---|---|---|---|---|---|---|

| 2.00 ounces | Magnum | 60 minutes | Boil | Pellets | 10.0% | |

| 2.00 ounces | Total Hop Weight | |||||

Yeasts

| Name | Lab/Manufacturer | Product ID | Form |

|---|---|---|---|

| Abbey Ale | White Labs | WLP530 | Liquid |

Equipment Profile Converted Keg, 10 Gallon/38 Liter Cooler Mash Tun

Mash Profile Single Infusion Mash, Light Bodied Beer, No Mash Out

Mash Steps

| # | Name | Time | Temp. | |

|---|---|---|---|---|

| 1 | Mash In | Infusion | 75 minutes | 150° F |

Fermentation and Aging

General Info

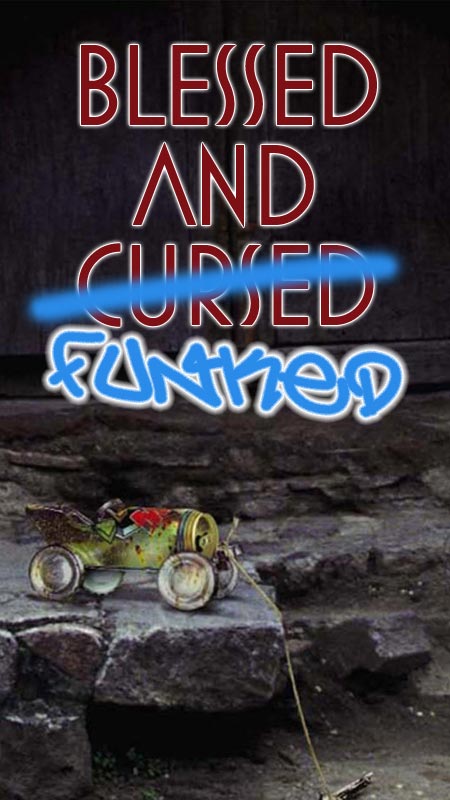

Turning lemons into lemonade...

The resulting beer after five months is distinctly tart; similar to The Devil You Know. Shit.

OK. So to make this a better thing - I'm going to rack the beer into a large fermenter, pitch some Brett B into it, add a couple French Oak spirals, and give it a year. Perhaps it'll blend well with the last batch of Blessed (probably should call it "Cursed" from now on) that I decided to sour.

Might be good fodder for raspberries.

Procedure

Single infusion mash at 150° F for 60 minutes.

Ferment at 72° F.

Once primary fermentation begins to slow, optionally make a syrup with the sucrose and a bit of water, boil, cool, and add to fermenter.

Special Procedures

Use 1 lb. dark liquid candi sugar to impart more dark fruit, molasses, and intense caramel flavors.

Use 1 lb. amber liquid candi sugar to balance the burnt-caramel flavors of the dark.

Adjust water by adding 5 grams calcium chloride in both the mash and sparge water additions. This will up the chloride amounts to bring down the mash PH to into the 5.6 range and to enhance maltiness in the finished beer. Amounts based upon 10 gallons each of mash and sparge water.